The smart Trick of Dust Extractor Vs Shop Vac That Nobody is Discussing

Table of ContentsSome Known Questions About Dust Extractor Vs Shop Vac.Some Known Incorrect Statements About Dust Extractor Vs Shop Vac The smart Trick of Dust Extractor Vs Shop Vac That Nobody is DiscussingExamine This Report on Dust Extractor Vs Shop VacUnknown Facts About Dust Extractor Vs Shop VacNot known Factual Statements About Dust Extractor Vs Shop Vac

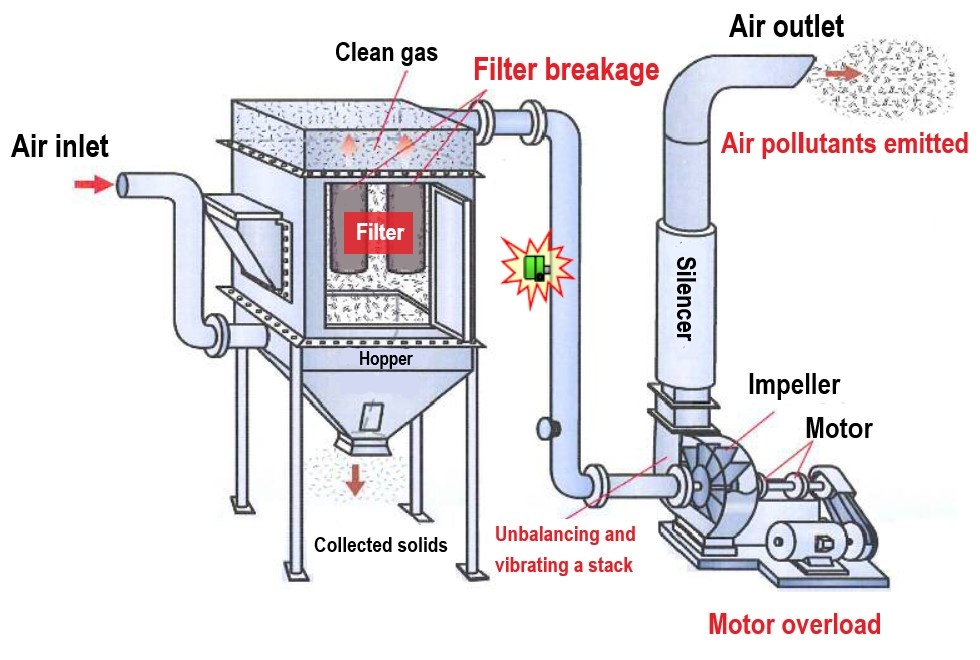

The difficulties for shop dust collection systems revolve around crystalline silica dust, carbon monoxide gas, and warmth, which are toxic combinations. These factors make conference air top quality criteria hard and requiring. As a result, when selecting a dirt control system for a foundry, the first factor to consider is the capability of the system to endure harsh as well as dangerous workplace problems.Other than the noticeable conditions, the selected devices needs to fulfill the regulations of OSHA, the EPA, and also the NFPA. To fulfill those requirements, dust collection systems utilize shakeout rooms, collection hoods, melt, mold pouring, cooling down hoods, and also exhaust stacks. Pleated bag as well as cartridge-style collection agencies have a very efficient filtration system in addition to a compact size and decreased pressure decrease.

Finish, or thermal spray, uses warmed material to metals to layer their surfaces. Dust collection systems for this kind of procedure must be especially developed to fit the kind of finish being used. The objective of the system is to regulate and lessen overspray and dirt. The typical thermal spray dirt control system uses ducts to move air to the collection tool.

What Does Dust Extractor Vs Shop Vac Do?

Though presumably likely to raise air flow as well as movement, this kind of remedy might be inefficient and waste energy. The design of the booth relies on the force of the air getting in the cell or cubicle. For most systems, it is necessary to have a small vacuum in the booth to stay clear of possible positive stress.

One more method is simply positioning the makeup air link on the top of the cubicle. Despite the design, it is essential for the cleaning of the air to have cross air flow. Similar to a cleanroom, airflow in a thermal spray cubicle can be either straight or downward, though the descending layout is best for dust collection systems. dust extractor vs shop vac.

The pharmaceutical market is a very controlled industry with extensive and specific regulations. Dust from pharmaceuticals is created mostly throughout the production as well as packaging of products - dust extractor vs shop vac. Each action of generating a medicine, that includes granulating, drying out, blending, pressing, layer, and grinding, creates big amounts of dust that need to be gotten rid of.

All About Dust Extractor Vs Shop Vac

HEPA filters are typically found in pharmaceutical dust control systems given that they are one of the most efficient and reliable. As with a foundry system, they are set up as a secondary protection to attain zero discharges. Reusing creates a lot of dust as a natural result of lessening items to their resources.

Dust stems after materials are shredded, squashed, or have paint or lacquer removed. All reusing facilities are called for to adhere to air high quality criteria. As they function to satisfy top quality criteria and also control contaminants, they have recognized that dirt control is a significant issue, bring about the wide usage of dirt collection systems to mitigate as well as consist of the issue.

How Dust Extractor Vs Shop Vac can Save You Time, Stress, and Money.

When makers select a dust control system, they are advised by manufacturers regarding the sort of click over here system that would best fit their needs considering that purchasing and also setting up a dirt control system is a significant financial investment. Particulate issue comes in a wide array of kinds, from silicon dirt to timber chips and sawdust.

Below is a brief listing of the sorts of particles that dirt collection systems can remove. Gypsum Gypsum requires a high-efficiency baghouse system capable of operating at temperature levels near 428 F (220 C). Felt Felt is utilized in clothing production as well as calls for dirt collection systems at three phases of the procedure.

Sawdust This is the most typical product removed by dirt collection systems. Cartridge or baghouse techniques can be used, with baghouse being the most effective.

The smart Trick of Dust Extractor Vs Shop Vac That Nobody is Discussing

Textile filter bags in a cartridge system are one of the most efficient go to my blog method for accumulating dust. Concrete Cement dust is developed throughout the motion and also transportation of the item. Dirt collection systems are covered to consist of the dust as well as tidy the air. Clay Clay dust is generated in the manufacturing of bricks.

With the introduction of dirt collection systems, workers are much safer and a lot more protected. Sugar Sugar dirt is the by-product of the production of sweet. Pulse jet systems are used to maintain the filters of the dirt collection system you could try these out particulate-free. The gathered product is eliminated and also collected in drums. Zinc Zinc dirt is produced in the galvanizing process.

Rumored Buzz on Dust Extractor Vs Shop Vac

Rice Dust Rice dust has very fine and also minute fragments that accumulate during the production of rice-based items. dust extractor vs shop vac. A dirt collection system is needed for the security and security of employees.